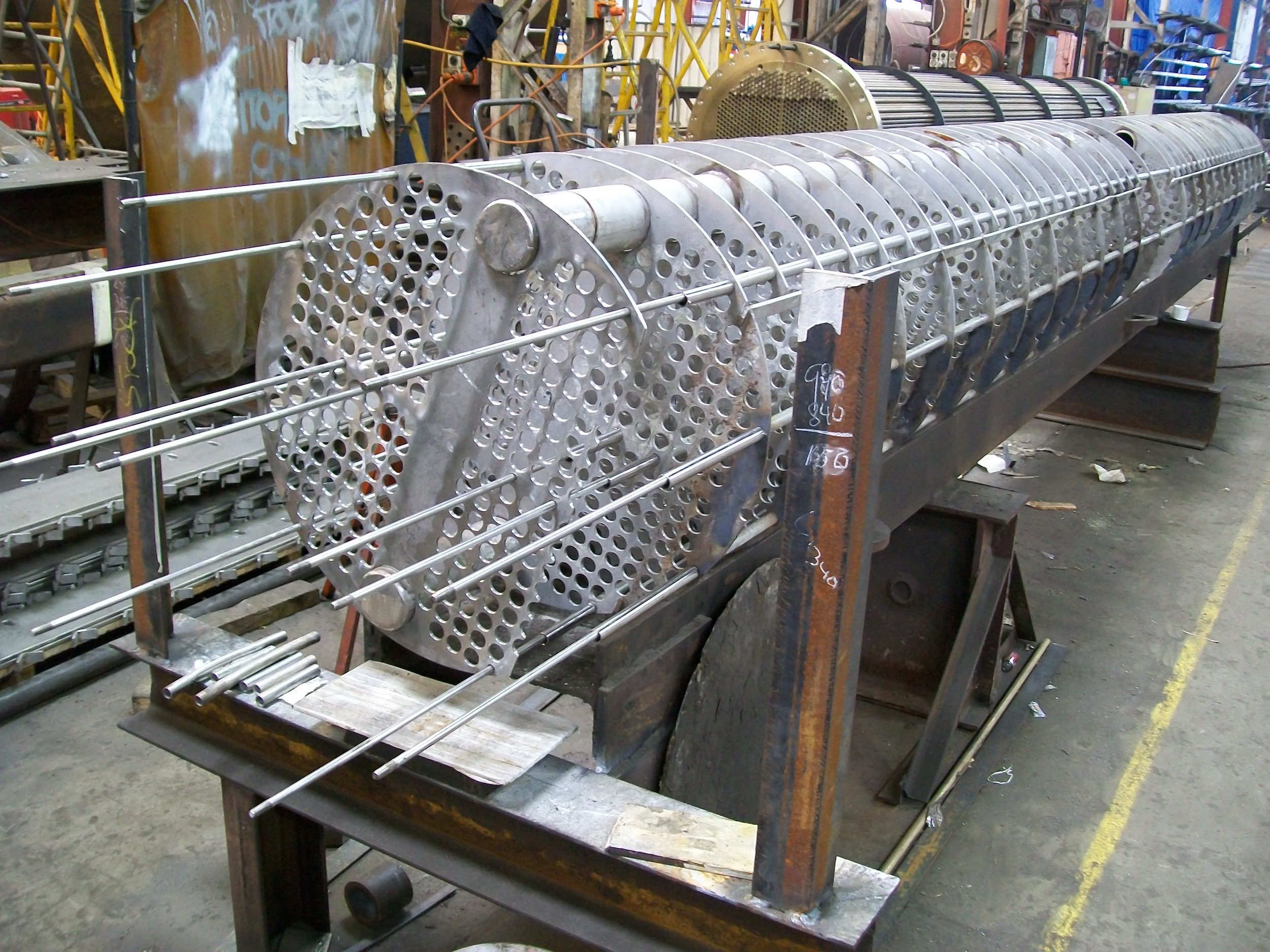

Bundle-Retubing

Our legacy in heat exchanger design and manufacture provides unmatched knowledge and insights into bundle re-tubing and repairs.

Bundle refurbishment posed many challenges which can start before the bundle has even been removed from the exchange shell through to tube punching and expanding into old tubesheet.

Retubing services and expertise are available for carbon, stainless and alloy straight bundles, U-tubes and air cooler fin fan configuration. Our workshop has the capacity and specialised tube bundle refurbishment equipment to accommodate small bundles with a few thin walled copper tubes, through to large diameter boilers housing several thousand tubes or header frames upto 6m wide.

Bundle refurbishment work undertaken by the LA Services team ranges from re-expanding or tube plugging to address minor leaks through to a complete bundle strip, cage or header refurbishment, re-assembly and hydro testing if required.

Case Study

Completed 2019

Packinox Bundle Replacement Project

The refurbishment of Caltex’s Packinox heat exchanger required a bundle replacement to solve efficiency problems.

To do this the 80mm thick head needed to be cut off then re-welded into position.

With asset down time being costly an accelerated welding method was required to be able to complete the refurbishment within a planned refinery shutdown window.

Request a Quote

Please allow at least 3-5 business days for us to prepare a budget estimate